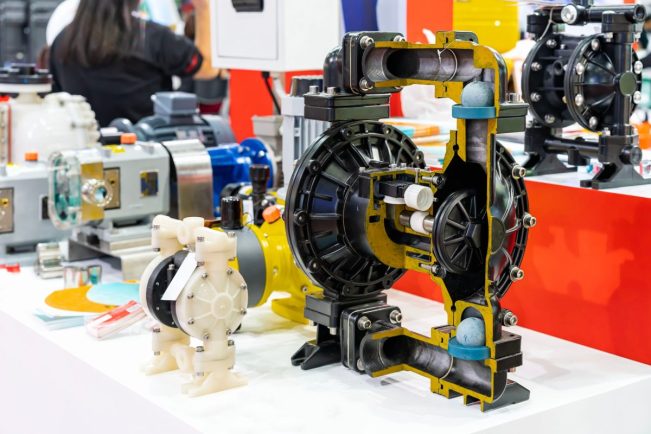

Diaphragm pumps, also called membrane pumps, are versatile and efficient devices widely used across various industries for fluid transfer.

They are highly valued for their ability to handle corrosive chemicals, viscous liquids, and slurries.

This beginner’s guide explains how a membrane pump works, parts, mode of operation, type, and applications.

What Are Diaphragm Pumps?

Diaphragm pumps are positive displacement pumps that transfer fluid due to pressure differences created by the diaphragm’s oscillating motion. The fluid is first drawn into the pump chamber and then expelled out of it. This action is generally mechanically, hydraulically, or pneumatically powered.

Key components of diaphragm pumps:

Diaphragm: This is the heart of the pump and is typically fabricated from a resilient material, usually rubber, Teflon, or another elastomer. The resilience of the material used provides flexibility to the pump.

Pump Chamber: This chamber houses the diaphragm and is filled with the fluid that is to be pumped.

Valves: The pump chamber has both an inlet and an outlet check valve. The valves allow fluid to filter into the pump chamber from the inlet and leave the pump chamber from the outlet in one direction, preventing backflow.

Drive Mechanism: It could be mechanical, hydraulic, or pneumatic to move the diaphragm.

How Diaphragm Pumps Work

The working principles of a pneumatic diaphragm pump are simple and can be summarised as follows:

Suction Stroke: The diaphragm retracts, creating a vacuum in the pump chamber. This pressure drop allows fluid to enter through the open inlet valve.

Discharge Stroke: The diaphragm pushes forward, reducing the volume in the pump chamber. At increasing pressure, the inlet valve closes, the outlet valve opens, and the fluid is forced out.

Continuous Cycle: The suction and discharge strokes immediately follow one another, ensuring a continuous pumping action and steady fluid transfer fluorescent penetrant examination.

Types of Diaphragm Pumps

Diaphragm pumps come in several varieties, with each type best suited for specific applications:

Air-Operated Double Diaphragm (AODD) Pumps

These pumps have compressed air that flexes the diaphragms. They can handle a wide range of viscous, corrosive, and abrasive fluids. Applications include the process industry in chemical processing and wastewater treatment in the food/beverage industries.

Mechanically Actuated Diaphragm Pumps

These pumps reciprocate the diaphragm mechanically, typically through a linkage with a crankshaft. They are considered reliable for applications requiring flow control, such as metering and dosing.

Hydraulically Actuated Diaphragm Pumps

These pumps use hydraulic fluid to displace the diaphragm. Their high-pressure ability is applied mainly to thick or highly viscous fluids or where high discharge pressures are required, as in oil and gas operations.

Advantages of Diaphragm Pumps

Diaphragm pumps have several advantages that make them among the most popular in various industries for the following reasons:

Versatility: Notably, diaphragm pumps can handle a wide range of fluids, from water and oils to corrosive chemicals and slurries. Their design enables them to pump viscous, abrasive, and shear-sensitive fluids without damage.

Self-Priming: Without previous filling with fluid, pumps can self-prime; as a result, they can start pumping immediately. This feature has favourable applications in cases where the pump goes through varying fluid levels.

Dry Running Capability: Unlike most other types of pumps, a diaphragm pump can run dry without any damage. It is in this trait that its use in purposes where there might be periodic fluid supplies becomes very resourceful.

Seal-Less Design: This design eliminates mechanical seals and, therefore, leakages. It also reduces maintenance time, making it a very safe and reliable option for use with hazardous fluids.

Portability: The majority of diaphragm pumps are lightweight; hence, they are portable, making it easy to take them around to different locations for use.

Applications of Diaphragm Pumps

Because of their versatility and solid construction, diaphragm pumps are applied for a myriad of uses in various industries:

Chemical Processing: Diaphragm pumps are ideal for transferring aggressive chemicals, including acids, bases, and solvents. Their ability to handle corrosive and abrasive fluids makes them indispensable in this sector.

Water and Wastewater Treatment: These pumps are used for dosing chemicals, transferring sludge, and handling various treatment chemicals in water and wastewater facilities.

Food and Beverage Industry: Diaphragm pumps are used to transfer food products, such as sauces, syrups, and beverages, due to their sanitary design and ability to handle shear-sensitive fluids without contamination.

Pharmaceutical Industry: In pharmaceutical manufacturing, diaphragm pumps are employed for precise dosing and transfer of chemicals and solvents, ensuring accuracy and purity.

Oil and Gas Industry: These pumps are used for transferring hydrocarbons, chemicals, and water in drilling and production operations. Their ability to handle viscous and abrasive fluids makes them well-suited for these demanding applications.

Automotive Industry: Diaphragm pumps are used in various automotive applications, including fuel transfer, coolant circulation, and fluid dispensing.

Maintenance and Troubleshooting

Even though diaphragm pumps are reliable, regular maintenance is necessary to ensure optimal performance. Checks should include routine inspections for diaphragm wear and tear, valve functionality, and the condition of the drive mechanism.

Some common problems associated with these pumps are:

Loss of Flow: This may occur due to a torn diaphragm, blocked valves, or air leakage in air-operated pumps.

Erratic Operation: Irregular pumping could be caused by an improper air supply in pneumatic pumps or faulty mechanical linkages in mechanically actuated pumps.

Leaks: These can result from a worn-out diaphragm or damaged seals. Proper checks and timely replacement of these components can prevent leakage.

Conclusion

Diaphragm pumps have been invaluable to many industries due to their versatility, reliability, and ability to handle a wide range of fluids. Understanding their operation and various types can help users choose the most relevant pump for specific applications. Proper maintenance and troubleshooting ensure continuous efficiency and reliability, even in strenuous environments.